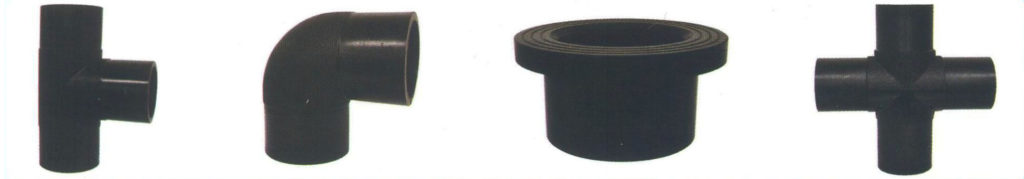

HDPE Pipes & Fittings

RADIANCE TECHNOPLAST PRIVATE LIMITED is a subsidiary of radiance group of companies. Radiance group has been engaged in real estate, construction and trading for the last four decades. The group has entered the hdpe pipe business and has developed solid dealer network across Tamil Nadu, Kerala, Karnataka and Andra Pradesh. RADIANCE TECHNOPLAST PRIVATE LIMITED product covers hdpe pipes and fittings, push on fittings, electro fusion fittings, compression fittings and butt fusion fittings. Radiance hdpe pipes equipped with most automatic extrusion lines for making pipes ranging from 16mm od to 355mm od of pressure range pn 2.5 to pn 16.

PE PIPES are one of the two largest thermoplastic pipelines available and by far the most versatile. Polyethylene is a wax like 3 thermoplastic with a density varying from a range of 934 kg/m 3 to 960 kg/m which is less then that of water. The only two additives that are added to polyethylene are carbon black with a limit of 2-3% to add some reinforcing effect to increase its weathering properties and some anti-oxidant to a limit of 0.3%. We mostly use black pre-compounded pe material. Hdpe having comparatively high molecular weight is high in abrasion resistance and impact strength. It is also very good in stress cracking resistance and has low creep rupture properties. It is excellent in insulation properties over a wide range of frequencies and good chemical properties.

PE (Polyethylene) Pipe.

Even in heavy-loaded areas, when only the strongest galvanized iron, cement pipe survive, plastic in the from of hdpe has scored beyond doubt as an ideal substitute. Hdpe is today, the internationally preferred piping material across an unbelievable range of applications (when strength & long life are key requirements). Hdpe is also capable of handling even semi-solid and gaseous effluents and displays unmatched resistance to corrosive chemicals. In other words where metal, cement and other forms of plastics fail to perform, hdpe pipes excel.

FEATURES AND BENEFITS OF RADIANCE PE PIPES

- Very low friction resistance to fluid flow and thus saves energy cost for pumping.

- “C” factor of radiance pe pipes is 150 (highest “c” value of 150 is recommended in william hazen formula).

- UV resistant. Low wear and tear and fully abrasion resistant. Remains free fro incrustation throughout the life span giving better flow always.

- Excellent impact resistant, withstand water hammer shocks and transverse loads due to thermal stresses.

- Suitable to withstand high fluid flow and external soil pressure. Chemically inert and hence resistant to most chemicals and hostile corrosive soils.

- PE pipes are easier to handle and install compared to heavier metallic or concrete pipes. PE is about one-eight, the density of steel and thus does not require the use of heavy lifting eqipment for installation.

- Bending radius is 25 times the pipe diameter. Excellent elastic properties ensure absorption of soil movements, stresses and Hydraulic pressure.

- Light weight facilitates easy handling and instant fixing. Joints obtained by Butt welding are homodenous and 100% leak proof. Offers life of minimum 50 years.

- Avaliable in single coil in lengths as required particularly the smaller diameter pipes. No additional joints, sockets, etc are required.

- Full joint traceability, ideal for renovation work through pipe bursting techniques, No requirements for protective coatings.